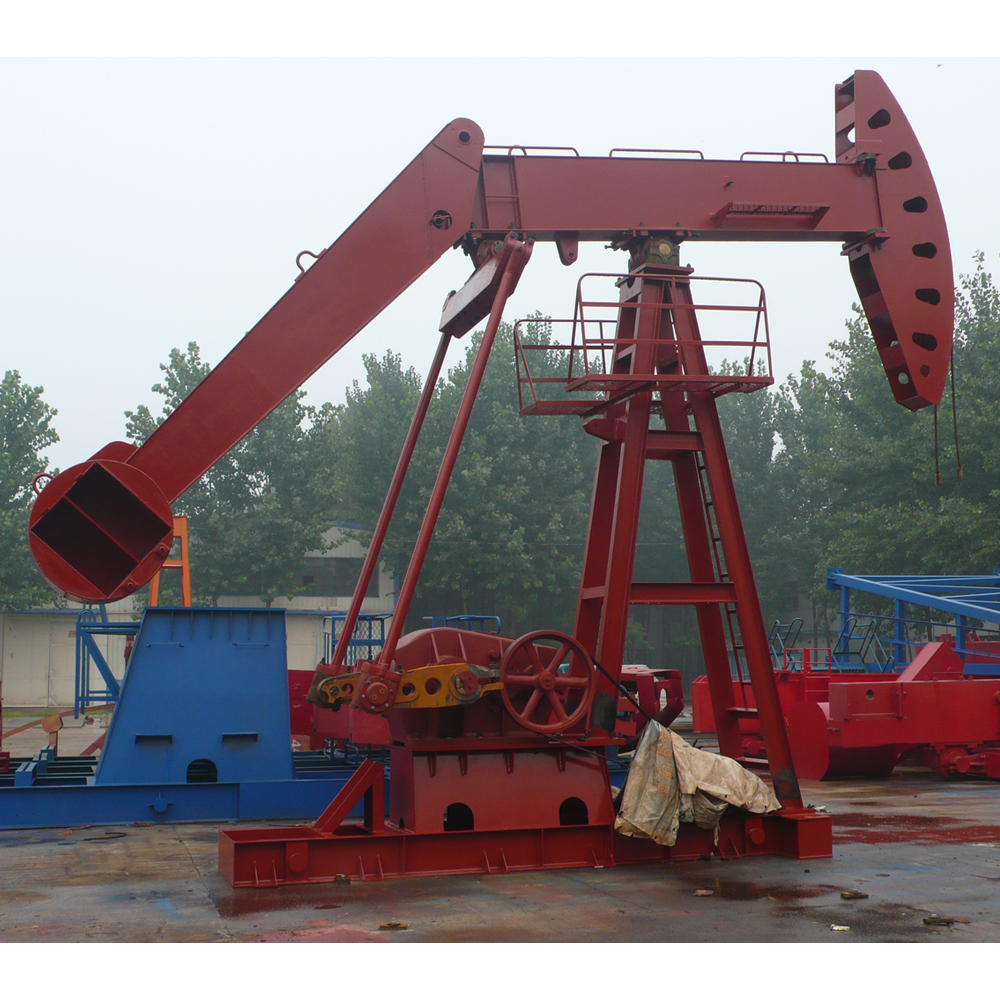

Pumping Unit

1.All the technical parameters are conforming to the provisions of the Standards 11E as developed by American Petroleum Institute (API).

2.The complete machine features rational structure, stable operation, low noise and easy operation and maintenance.

3.The walking beam adopts box or H section steel structure, which is high in strength, rigidity, and carrying capacity.

4.The retarder adopts herringbone involute or double-circular-arc gears, which are conducive to enhancing precision and affordability and extending service life.

5.On the central support as well as the beam-balanced support are mid-wide roller bearings, which are characterized by high leak tightness and holding capacity; the beam balanced bearings and the crank pin bearings are capable of self-aligning in order to reduce the error occurring during installation as well as the vibration of the operating oil pumping unit.

6.Tilting/hanging/up-stand/self-yielding horse-heads are available.

7.The tower-shaped frame is high in stability and easy to install on site, and its retractable structure is particularly convenient for packing and transportation.

8.The crank counterweight is provided with rack and pinion transmission, which is adjustable, light and accurate.

9.The internal swelling/external locking brake equipped with safety devices features flexible operation, rapid braking, and high security and reliability.

10.Pressure plate-mounted and bolt-fixed bases are available for users.

11.Non-rotating wire ropes can be used during hoisting in order to avoid any twists.

12.Both common V-tapes and joint narrow V-tapes are available.

13.Power machines include common electromotors, variable frequency electric motors, energy-saving motors, and diesel or natural gas engines.

Model | APISpec.11E | Rated Suspension Center Load | Retarder Torque | Stroke | Frequency of Stroke | Motor Power(KW) | Quality of the Complete Machine(T) |

CYJ5-1.8-13HB | 114-109-74 | 50 | 13 | 1.8 1.5 1.2 | 6 9 12 | 15 | 9.5 |

CYJ6-1.4-13HB | 114-133-54 | 60 | 13 | 1.4 1.2 1.0 | 6 9 12 | 15 | 11.2 |

CYJ6-1.6-13HB | 114-143-54 | 60 | 13 | 1.6 1.4 1.1 | 6 9 12 | 15 | 11.5 |

CYJ8-1.6-13HB | 114-173-64 | 80 | 13 | 1.6 1.4 1.1 | 6 9 12 | 18.5 | 12.4 |

CYJ6-1.8-13HB | 114-143-74 | 60 | 13 | 1,8 1.6 1.4 | 6 9 12 | 15 | 12.4 |

CYJ5-2.1-13HB | 114-119-86 | 50 | 13 | 2.1 1.8 1.4 | 6 9 12 | 15 | 12.4 |

CYJ8-1.6-18HB | 160-173-64 | 80 | 18 | 1.6 1.4 1.1 | 6 9 12 | 18.5 | 12.7 |

CYJ6-1.8-18HB | 160-143-74 | 60 | 18 | 1.8 1.6 1.4 | 6 9 12 | 15 | 12.7 |

CYJ8-1.8-18HB | 160-173-74 | 80 | 18 | 1.8 1.6 1.4 | 6 9 12 | 18.5 | 12.7 |

CYJ9-1.8-18HB | 160-200-74 | 90 | 18 | 1.8 1.6 1.4 | 6 9 12 | 18.5 | 14.6 |

CYJ8-2.1-18HB | 160-173-86 | 80 | 18 | 2.1 1.8 1.6 | 6 9 12 | 22 | 14.6 |

CYJ8-1.8-26HB | 228-173-74 | 80 | 26 | 1.8 1.6 1.4 | 6 9 12 | 18.5 | 14.6 |

CYJ9-1.8-26HB | 228-220-74 | 90 | 26 | 1.8 1.6 1.4 | 6 9 12 | 18.5 | 14.6 |

CYJ10-2.1-26HB | 228-213-86 | 100 | 26 | 2.1 1.8 1.6 | 6 9 12 | 22 | 17.9 |

CYJ11-2.1-26HB | 228-246-86 | 110 | 26 | 2.1 1.8 1.6 | 6 9 12 | 22 | 17.9 |

CYJ6-2.5-26HB | 228-133-100 | 60 | 26 | 2.5 2.1 1.8 | 6 9 12 | 18.5 | 13.8 |

CYJ8-2.5-26HB | 228-173-100 | 80 | 26 | 2.5 2.1 1.8 | 6 9 12 | 30 | 15.5 |

CYJ10-2.5-26HB | 228-213-100 | 100 | 26 | 2.5 2.1 1.8 | 6 9 12 | 30 | 16.4 |

CYJ10-3-26HB | 228-213-120 | 100 | 26 | 3.0 2.5 2.1 | 6 9 12 | 30 | 17.9 |

CYJ10-2.1-37HB | 320-213-86 | 100 | 37 | 2.1 1.8 1.6 | 6 9 12 | 30 | 17.9 |

CYJ12-2.5-37HB | 320-256-100 | 120 | 37 | 2.5 2.1 1.6 | 6 9 12 | 37 | 18.5 |

CYJ10-3-37HB | 320-213-120 | 100 | 37 | 3.0 2.5 2.1 | 6 9 12 | 30 | 18.1 |

CYJ12-3-37HB | 320-256-120 | 120 | 37 | 3.0 2.5 2.1 | 6 9 12 | 37 | 19.5 |

CYJ10-3-53HB | 456-213-120 | 100 | 53 | 3.0 2.5 2.1 | 6 9 12 | 45 | 21.0 |

CYJ14-3-53HB | 456-305-120 | 140 | 53 | 3.0 2.5 2.1 | 6 9 12 | 55 | 24.5 |

CYJ12-3-53HB | 456-256-120 | 120 | 53 | 3.0 2.5 2.1 | 6 9 12 | 45 | 23.0 |

CYJ12-3.6-53HB | 456-256-144 | 120 | 53 | 3.6 3.1 2.7 | 6 9 12 | 55 | 24.0 |

CYJ14-4.2-53HB | 456-305-168 | 140 | 53 | 4.2 3.6 3.1 | 6 9 12 | 55 | 26.6 |

CYJ14-3.6-73HB | 640-305-144 | 140 | 73 | 3.6 3.1 2.7 | 6 9 12 | 55 | 25.0 |